| Motor IssuesDecember 8 2007 at 8:49 AM |

Mark Weller (Login mweller) |

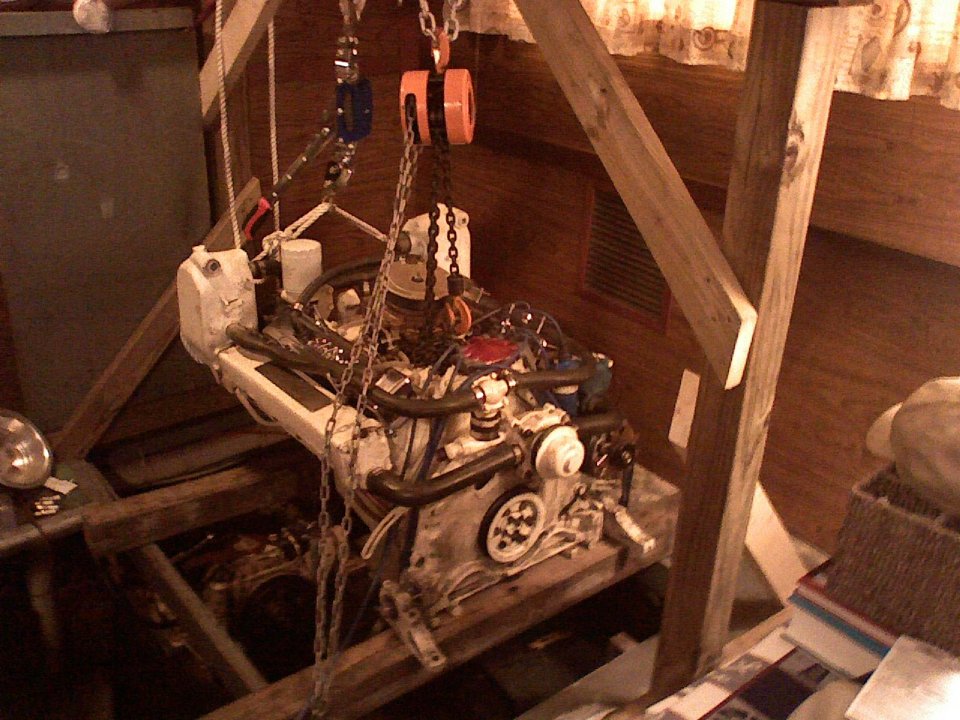

| As Paul can attest to I had some motor issues this summer with the rebuilt motor I did last winter. At the end of the season I found the problem a bad "rear" main seal actually its the front seal on a Q. But I thought I might share some pics of the motor and hoist system I used to replace the seal it's the same system I used to pull the engine last year. Anyway the motor is back in the boat and mounted back up to the tranny etc. The frame I used is rather simple 4x4's for the legs, uprights and top piece 2x4's for the bracing. A small chain hoist 1 ton and a come along to lift the rear of the motor. As you can see I used a few more 4x4's to rest the motor on during the work also for safety's sake I kept some tension on the 2 lifting devices when I was laying down in the bilge dropping the pan and replacing the seal. We did the job in about 3 days including detatching all wiring cables etc lifting the motor and replacing it.

And another view

edit comment:

edit comment:

Due to obvious liability and safety concerns, nothing in this post or those that follow shall be construed as a structural suggestion, recommendation, or endorsement, from Mark, the Chris Craft Commander Forum, Inc, chriscraftcommander.com, or any other participant here on the forum. We place this notice here in the interst of safety and caution, and by doing so encourage each person who is contemplating a lift of any kind, to use their own best judgement, not rely on anything posted here, and get professional help if necessary.

Thank you for your understanding,

Paul, forum host

This message has been edited by FEfinaticP on Jan 29, 2008 3:58 AM

|

|

| | Author | Reply | Paul

(no login) | Lots of methods to hoist motors in and out ! | December 8 2007, 4:22 PM |

Hi Mark,

Looks good, and yes, I saw the results first hand. You did a nice job on the rebuild, for sure, and I hope those sweet Q motors run a good many years for you troublefree.

The hoist construction looks good too, I like the fact that you have everything cross braced.

Here are a couple of photos of a real beast I pulled out a few years ago. The darn flathead six cylinder Hercules weighed in at almost 700 pounds (with transmission and exhaust). I have two special beams installed in my basement, shown here, to take loads like this (independent from the floor structure above). It's very handy for swapping motors in cars and boats, and for lifting 427 motors to do prep work too. I no longer use the small blue hand winches for things like this, by the way.

Here’s the motor that went in, after the old Hercules was removed. The main framework of this boat was carefully reinforced with oak, epoxy, and stainless steel, prior to installing this one. The motor mounts fit up perfectly, since this very model of boat received V8 power a few years later. The new V8 was designed to fit the boats interchangeably, and you could order a flathead six or the eight for the same hull. Needless to say, this is one very rapid 17’ Chris Craft. It has put a frown on many a fancy new ski boat owner who tried to pass "the old wood boat", tee hee.

Here’s a shot of that leveling device between the winch and the motor, very very handy thing to have around the house. Who knows, your wife may even need this for something! (Great stocking stuffer for any gal, lol). I removed the distributor cap to keep things from binding, and stuffed my shirt in there to keep a cushion in place. Aw heck, it was just too much work to pull that shirt back out of the photo, ha!

Regards,

Paul

|

| Paul

(no login) | Here's the 700-pound Hercules that came out of that 17' Chris Craft ! | December 8 2007, 4:47 PM |

Here are the same small mechanical winches I used on the Skiff transmission, removing this 680-pound Hercules flathead six. The small block Chevrolet that went back in, had two hundred more horsepower than this one, and it didn’t weigh as much!

At the time, I used two of these winches in tandem for a little more security, but I would have rather used the 2-ton “mother of all come-alongs” I now use for heavy lifting.

This was a fun project! (Yes, the transom was being replaced at this time too).

Paul

|

| Paul

(no login) | Here's another hoist design ( photo ) | December 8 2007, 4:35 PM |

Here’s what Charles used in Martiniqe, to haul out a pair of 427 motors and reinstall them. The hoist shown, is typical in the marine industry, I have seen scores of these in one form or another. This one looks like it has been proven over a lot of years.

Although these motors are heavy, the actual weight really isn’t beyond the capability of many types of hoists. My concern is always to look at triangulation of the design, and to avoid any single welds that take all the moment reactions in the event the motor wants to move forward or aft.

I have seen some of these designs, that have a single main vertical member terminating at the base with a single weld, and I’m not sure I’d even want to lift a small block with one like that. In the design and construction industry, I’ve seen waaaay too many moment connections like that fail. The key is to be safe; triangulation (and gussets) will add a lot of stability to any pull like this, whether the hoist is steel or wood. This one worked well for Charles.

|

| Tom Slayton

(no login) | A wood truss can be very strong.... | December 15 2007, 1:46 PM |

...if it is built properly. I agree that lateral loads, anticipated and unanticipated, need to be dealt with (with cross bracing). Nothing wrong with a wood truss at all, as long as it's strong enough, same can be said about steel.

Tom

|

| Paul

(no login) | Engine hoist | February 18 2008, 7:56 AM |

The more I see and hear about the various methods of lifting heavy marine engine parts, the more I think it may be money well spent to purchase a device like this. It has the benefit of working with low overhead clearances. In other words, you don’t have to suspect a hoist below an A-frame, because the hydraulic lift is what pushes the top bar up. In addition, you have room for the adjustable leveling device shown in the image.

I have not used one of these devices, but I have used the leveling device on more than one occasion and they’re great.

In the event I was going to pull motors, I would give this serious consideration. The unit looks like it would be safe if operated in an appropriate and safe manner, and it could be sold afterwards to recover some of the cash it took to buy it. In the end, when you consider the safety factor and the resale, this would appear to be economically feasible. Any A-frame built, would also cost money, the design and structure would be somewhat untested, and in the end you would be stuck with the A-frame without much of a chance to re-sell or ever re-use it.

Here is a link to Northern Tools (below), showing more detail on this “less than $200 investment”. I also saw one like it at the Tractor Supply Store (TSC) here in Tennessee last week-end, and looking at it in person gave me some level of confidence that it would work in a marine application, if plank runners were set up for the wheels accordingly. I would consider installing uni-directional casters on the rig, to assure it pulled straight out once it was loaded.

I have a use for my automotive projects as well, so this may be something I get into sometime in the future. Yes, I’m thinking about installing a V8 in that 1974 TVR some of you may have seen in my basement shop, and yes, there are two 427 motors sitting on crates right next to the car. I’m thinking about a hi-po 289 right at the moment, because that motor was an option in the car. It could hit 60-mph in first gear with one. However, if one of those 427 motors will fit……………..hmmmm, I better get out the measuring tape again, eh?

Anyone ever use something like this in a marine application? With a 4000 pound capacity, it should be able to lift out pieces of a marine powertrain with a good safety factor. I don’t think I would try hauling out the motor, manifolds, and transmission in one chunk, especially one of those big dogs, but stranger things have been done.

Here's that link to Northern

http://www2.northerntool.com/product/200305213.htm

Regards, Paul

|

| Paul

(no login) | This looks like the same thing for $159 | February 18 2008, 8:07 AM |

Having just posted the note above, I thought I'd take a look at the TSC device I saw the other day. It appears it's the same idetical thing Northern is selling, and the price looks a bit better. The Northern unit, however, seems to come with a free engine leveling device, and that would be a nice deal.

http://www.tractorsupply.com/webapp/wcs/stores/servlet/ProductDisplay_10551_10001_28141_______14297%7C14311%7C28141?listingPage=true

http://www.tractorsupply.com/webapp/wcs/stores/servlet/ProductDisplay_10551_10001_28141_______14297%7C14311%7C28141?listingPage=true

I would think that if you grab the motor block snugly with as little excess chain as possible, this device would make easy work of pulling out a marine motor. Again, not having used one in a marine application, I'll defer to anyone who has. Anyone?

Regards,

Paul

|

| Howard

(Login HowardEchols38) | Engine hoist issues | February 18 2008, 8:46 AM |

Paul,

I share your thoughts about safety and utility on this issue. The usual truss devices I have seen around the marina are good for lifting straight up, but dangerous when they are pulled sideways. Some of them look like they are apt to split apart, and some are downright dangerous. I think you could lay down some 2x10 tracks to extend across the engine bay and onto the aft deck, or some sort of a ¾” plywood floor to help take the loading, and this engine hoist would stand a chance of working.

I have not had the occasion to pull anything out of our engine bay, and quite honestly, I hope I never do. If I do, however, I will certainly consider going this route.

Howard

Huntsville, AL

|

| Paul

(no login) | Here are some photos of the lift | December 8 2007, 4:43 PM |

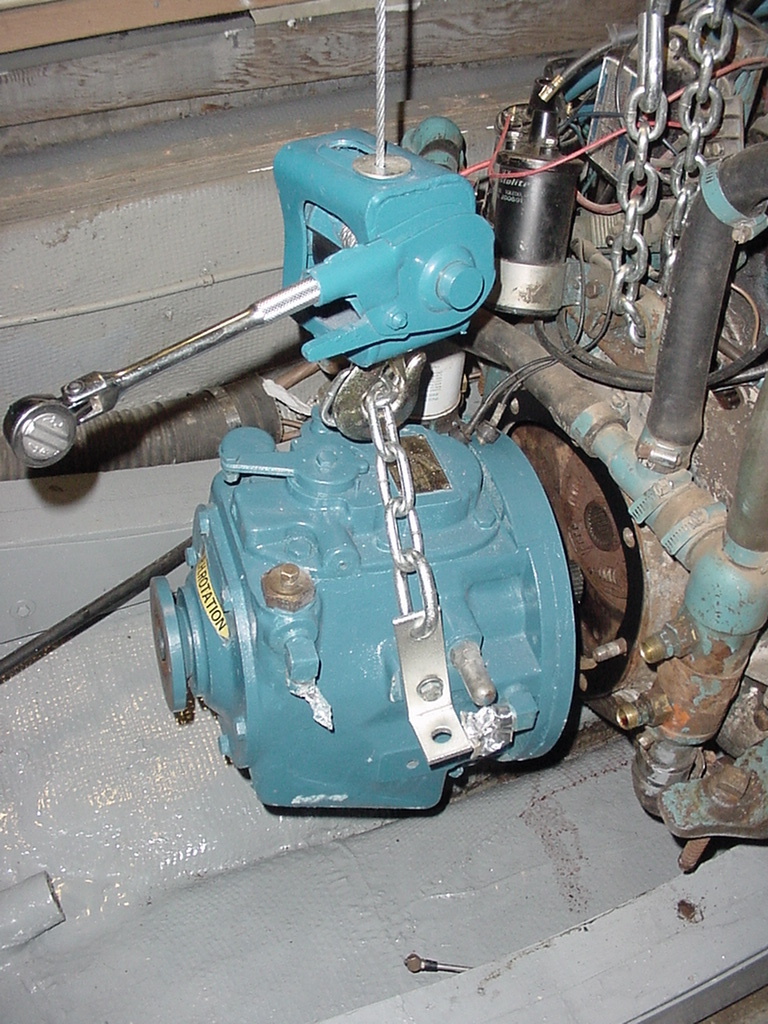

Here are a couple photos of the small block being lifted during my 1966 20’ fiberglass Sea Skiff restoration project. I used a leveling device between the winch and the motor to tilt things around to make it easy, just like pulling a motor out of an auto. The small blue hand winches were used on small stuff like the transmission.

That transmission may look small, but the darn thing is HEAVY. Tossing around iron like this is not without risk, it pays to take your time, double up on things, and be safe. The motor was lifted by a pair of 2x10s, number 2 yellow pine, spanning about 9’ from one side of the boat to another, stabilized in the center with a 4x4x24. They were braced off the structure of the shed to be sure things would not move laterally. Verticals were 4x4 #2 yellow pine, and probably grossly over-engineered, just the way I like it.

Fun on the farm !

regards, Paul

|

| | Current Topic - Motor Issues |

| |

|

|